Creating Tech Packs with Heather Panetti

Share

Looking to develop your own product, but not quite sure to begin? Learn the ins and outs of creating a tech pack with our Senior Approvals Manager and Custom Cut & Sew Director Heather Panetti, who has over 15 years of experience in the industry.

What IS a tech pack, exactly? What does it all include, and why is it important? What tools are needed to create one?

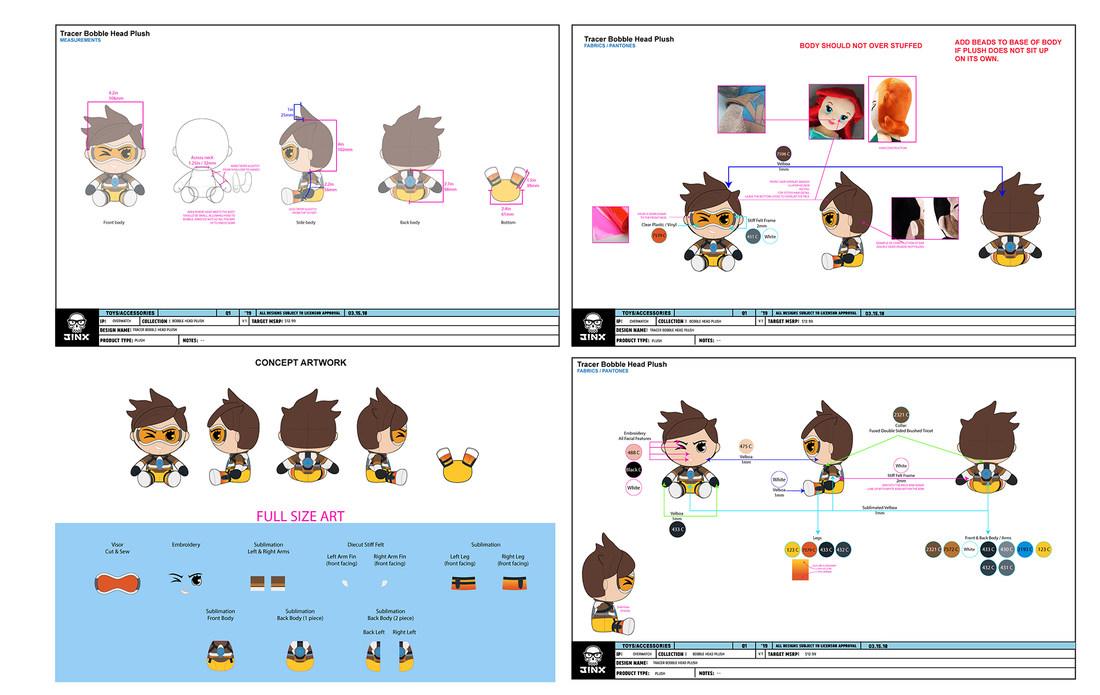

A tech pack is a Technical Packet that provides a manufacturer with directions on how to make a product. It breaks down the construction of a product like a recipe for baking - you need to provide the informational building blocks for how to make something from scratch. The goal is to take an idea from concept and clearly communicate direction for how a garment will be constructed so you have a sample that can be mass produced and sold to retail stores.

In my opinion, it’s important to provide a manufacturer with as much information about a design as possible. The less questions a manufacturer has, the better! However, even with the amount of experience I have, I still make mistakes and that's okay.

A tech pack can include multiple things but it just depends on what you want to make. Let’s use a caftan as an example - a caftan is a long rectangle shaped tunic. A rather simple design but a lot goes into it:

- What type of fabrics and how much does yardage cost?

- Will the fabric be from a stock, or do you want a custom print that involves creating art?

- What colors are being used and color matching to a Pantone code? The most common is PMS (Pantone Matching System), but there's also TCX (Textile Cotton), and TPG (Textile Paper). This is all personal preference, but manufacturers may only use specific types like PMS. Pantone runs the world of colors because the whole design & manufacturing world uses their code system to communicate colors in a global way (wow Pantone tangent)

- Are there any trims like zippers, buttons, or decorative trims like beads?

- What size range is needed to accommodate all body types?

- How about labels? Everything needs a branded label, a size label, and a care label.

Once I've narrowed down the facts of the garment, I can start the technical illustrations which the industry calls, “flats”. These are vector based illustrations that show technical information like:

- Seam Lines, where they’re placed and what type of seam is used

- Type of stitching for seams

- Info on how hems are finished

- How and where trims and labels are applied

- Providing rough measurements on the sample size (Base Size)

As I'm illustrating the flats, I'm visually deconstructing and reconstructing a garment in my head to be able to communicate in illustration form as much as possible. The manufacturer has an easier time understanding this method because most manufacturers are overseas and English is not their first language. Pictures are universal!

There are some key tools you’ll need like Adobe Illustrator or any design based program. A dress form and measuring tape, and knowing how formulas work in Excel is a plus for doing spec sheets. A spec sheet is the full size range of measurements from XS - 5XL. People don’t grow up and out, we grow all around, so determining specs can be the most difficult part of any tech pack. If people's bodies are not taken into careful consideration, you end up with a size M that looks pretty normal but by the time you get to a 5XL, a sleeve will look super long and extra wide, being too large for the 5XL person and that’s not a good feeling. People should feel good about themselves in the clothing they wear; at least that's what I want for them.

Is there any sort of research involved in establishing a tech pack?

Oh my gosh, yes! I’m looking at similar silhouettes online, pulling garments from my own closet to see how a seam is finished so I can illustrate it properly. You have to research fabric options because cost will always be a factor. I also reference different size charts online so we can build a well fitted garment that fits ALL body types.

Most companies work 1+ year ahead and a designer / tech designer needs to be aware of upcoming trends for future forecasting. This is a game we all have to play if you want retail placement unfortunately.

Walk us through your career! How did you get into this industry, and where did you start? Where all did it take you, and how did you land at Dual Wield Studio?

Sips coffee and crack knuckles, let me take you on a 16 year journey.

I’ve been into fashion design since I was toddler drawing stick figures with the fanciest hats while sitting on my grandmother’s lap. By the time I was in middle school, I was hand sewing my own shirts from extra fabric my mom had laying around till she bought me a sewing machine. Then in high school, I made my own prom dress. I knew what I wanted to do in my adult life and I fought tooth and nail to make it happen, even when others told me I would never make it because of XYZ reasons… I just fought harder to get what I wanted and to prove them wrong! You can literally do whatever you put your mind and soul into but it’s not easy. I was willing to sacrifice leaving home (Maine) to find my own path without help from family.

I eventually found my way to California in 2004 and saw a TV ad for a Project Runway type of competition that a local fashion school (Fashion Careers College) was hosting to gain student interest. Well, I signed up and won 2nd place which provided me with the smallest scholarship but that was my in, the school scooped me up and I started classes a few months later.

For a high school underachiever, I sure was a fashion school overachiever lol. I volunteered and participated in every event I could and eventually was part of a selected few that were the school’s go-to for designing garments for various fashion shows. This allowed me to design outfits for local celebrities & Make-A-Wish kids who wanted to be in a fashion show. I did a charity fashion event for Becky’s House, a foundation that helps women and children escape abusive situations. I’ve participated in high end fashion events at the Timken Museum of Art called, The Art of Fashion. We designed garments based on our interpretation of historical artworks.

After completing my fashion program in 2007 I got hired at a massive Halloween costume company called Disguise. I started as Assistant Designer then after some years I was promoted to Costume Designer. I designed costumes for so many awesome IPs like The Simpsons, Super Mario Bros., Power Rangers, The Powerpuff Girls, Transformers, Disney… so much Disney. After spending 7 years at Disguise, it was time for me to move on.

You can still find my designs in stores and online today. I’ve even seen photos online of celebrities wearing my costumes like Gisele, Kendall Jenner, Lauren Miller & Seth Rogan, Daniel Tosh & more!

This takes me to J!NX in 2015ish, but it’s important to note that anyone starting in the costume industry will have a hard time finding a transitional job into apparel design due to different construction methods and costumes being famously cheap quality. The licensing industry as a whole can be looked down on by mid to higher end apparel companies.

JINX was a mix of mid-high end apparel for gamers, and they had all the heavy hitter game licenses at the time like Minecraft, WoW, Overwatch, The Witcher, Halo and so on. They hired me as a Cut & Sew Designer because I already had experience in designing and tech’ing licensed products. So they took a chance and were willing to deprogram me from my Halloween costume mindset. There, I met my Cut & Sew Lead, Andri (this name is important later). Andri is a rad person who was tough but took the time to help me adjust and set high expectations for a growing cut & sew program. I truly respect Andri and will always appreciate the guidance they provided.

The next job chapter in life was H3 SportGear in 2018. The name alone is funny because we never designed sportswear, just licensed apparel, but I'm getting ahead of myself. After I got laid off from Jinx, a former Jinx coworker reached out saying his new place of work was looking to start a cut & sew program from the ground up. I seized the opportunity, but WOW did it backfire. So many red flags popped up before I even started but eventually I did the best I could with hardly any resources or support from management. I’m still traumatized by this place and will not dwell on it but 2 years later COVID arrived and my program and job got eliminated due to cutbacks.

Towards the end of the pandemic when companies started operating again, I found 2 incredible freelance jobs while on the hunt for a full time gig. One was working with a former Disguise coworker who started their own small business called, The Oblong Box Shop. I did their tech design and we even designed a collection together. I never had so much fun doing tech design before and I started loving it.

The other was doing tech design for a company called, The Vertical Collective, a woman owned and operated business. These women are so powerful, it was kinda intimidating but I forget I am too lol. They brought me on for a massive project for their client, MANSCAPED. This is a growing luxury underwear brand gaining global recognition and I single handedly created a well fitted boxer brief with incredible reviews. I had never worked on men’s underwear before but I freaking crushed it! The line I tech’ed is so good, they were featured on this last season of RuPaul’s Drag Race. The Pit Crew was wearing underwear I crafted to perfection and I freaked out with excitement.

Remember Andri from earlier? Well they’re back. While filling my days with freelance work, one day in 2021 Andri texted me out of the blue telling me about a job opportunity a friend of theirs was looking to fill and they thought I would be a good fit. It was not a design job but it was working with an IP and managing the approvals department for the mass market merchandise program. Since I had so much licensing experience and I’m kind of a hard-ass when it comes to following rules, Andri recommended me to their friend, Zara.

Zara was already working for Dual Wield Studio and passed my info along to Rowan, our CEO & Co-Founder. I wanna say within 2-3 weeks I went through the interview process, met the team and was hired. I jumped in head first and was thrilled to have a job after being out of work through the whole pandemic, I didn’t care it wasn't a design job. I was just grateful for an opportunity and was intending to find a design job at some point but the more I learned about the company and the people I work with the more I wanted to stay. I had never worked for a company that cares so much about the people and products we’re putting out into the world and there are times I think this job is fake and I'll wake up from this dream.

Now that I've been at Dual Wield Studio for a couple years, I get to watch this small company grow in a healthy and responsible way. We’re at the point now where I am building a cut and sew category from the ground up with all the support I could ask for.

So the job I thought would be temporary is now permanent. You will have to pull me away kicking and screaming because I love and respect this company so much that I'm here for the long haul. I technically manage 2 departments and it's a lot of work, but I can honestly say for the first time in my 16 year long career, I love what I do and who I do it for. Sounds cheesy but it’s true.

For someone that was looking at breaking into the clothing design industry, what advice would you give them?

Finding a school that works for you will be huge. If school is not an option for you, find a mentor who is willing to help you. If it helps to know, I only have an Associates Degree in Fashion Design, but the experience I have now opens WAY more doors.

Personally, I would recommend learning how to use Adobe Illustrator or any design based programs because everything is done digitally nowadays. I see friends from fashion school falling behind because we were taught how to do everything manually by hand. Learning Illustrator outside of school was my biggest hurdle.

Learn the basics on how to sew and make patterns. If you do not understand how a garment is constructed or how the pattern should look, you will have a difficult time communicating your needs to a manufacturer. Fashion design is more than drawing a beautifully rendered fashion illustration, you also need a basic knowledge on how to make a garment on your own. It’s a hard truth but an important one.

Oh, and maybe one of the most important things ever; learn to take constructive criticism for your work. Designing apparel is like spending time on a massive art piece and it can hurt when people tell you to change something that you spent so much time working on. Having the understanding that it’s not personal but it’s needed for a larger reason, will help you more than you know. Everything costs money and when you’re in mass market manufacturing, staying within a price point is very important.

Last helpful tip is to practice public speaking (eww), because there will be a time when you have to present a design or collection to a group of people and you will have to confidently speak through the collection and ultimately sell it to the group.

Do you have any examples of tech packs you’ve done that you can talk about with us that you’re particularly proud of?

Lol of course I do! Due to NDAs I can’t show you anything recent but I do have fun things that have already been released into the world like the caftan I mentioned above. I can also show some other things from J!NX since they are no longer around and I don’t have to worry about NDAs.

(Ask us for further files if you need!)

- Where can we find you/your work online?

You can find my work here and I started my own print on demand clothing line that can be found here.